When Yamaha designed the T-Max 560, they created an excellent product; it’s no wonder it has been so successful among maxi scooter enthusiasts. The T-Max is a best-seller among the two-wheelers from the Iwata company and is one of the most popular on our roads.

Further improving the work of Japanese engineers is no easy task. To succeed, attention must be turned to details considered marginal, such as the connecting hoses between the airbox and the throttle bodies of the electronic injection.

At least, that’s what we did.

Sacrificing power? No, thanks.

Optimizing the airflow between the airbox and the throttle bodies contributes to better engine performance. However, this involves a series of fluid dynamic studies, from empirical analysis to steady CFD (Computational Fluid Dynamics) and practical tests on the dynamometer.

In these kinds of studies, the classic “short blanket” problem often arises: to achieve improvement at high revs, the mid-range torque is sacrificed. This is why, in an initial step, we discarded a prototype that allowed for a substantial power increase at high revs but “emptied” the torque curve in the mid-range.

In Malossi, we started from the less “extreme” prototype, where our engineers determined the best configuration of the outflow coefficient through, precisely, steady CFD analysis.

Are you wondering what steady CFD analysis is? It’s a study that analyzes fluid behavior under constant flow conditions. With this tool, it is assumed that all variables – such as temperature, speed, and pressure – remain unchanged over time. In simple terms, steady CFD simulates the use of the product under “ideal” conditions to understand how fluids will behave inside the duct.

Malossi beats the original (and competitors)

Although empirical, CFD analysis provided us with useful information to reach the final prototype: a hose with a shape favoring a more linear and less curved duct, aiming for maximum performance at high revs while minimizing pressure losses.

And what material could we choose for the realization, if not FKM? FKM aka fluoroelastomer is known for its extreme resistance to chemical agents (such as hydrocarbons), high temperatures, and deterioration over time.

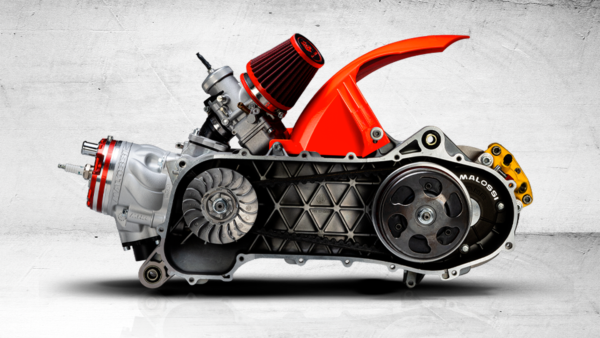

The intake hose for T-Max 560 code 0519910 must support constant and intense vibrations. That’s why we opted for a SHORE A 75 hardness, which is a perfect blend of the required resistance and flexibility characteristics. Additionally, the ribs on the Malossi hose help maintain shape under load and absorb impacts and pressures, preventing cracks or breaks. Can you guess which color we chose to produce our FKM hoses? Malossi Red, of course!

Why choose the Malossi intake hoses for T-Max 560

The Malossi hose code 0519910 improves the performance of stock T-Max engines. Still, it performs best on engines using modified exhausts – like Malossi Wild Lion – and more efficient air filters – for example, our W BOX code 1419312B – because it optimizes the intake system for vehicle modifications.

Get ready and go: now you know what to do to make your T-Max roar like never before!